What is a life cycle analysis?

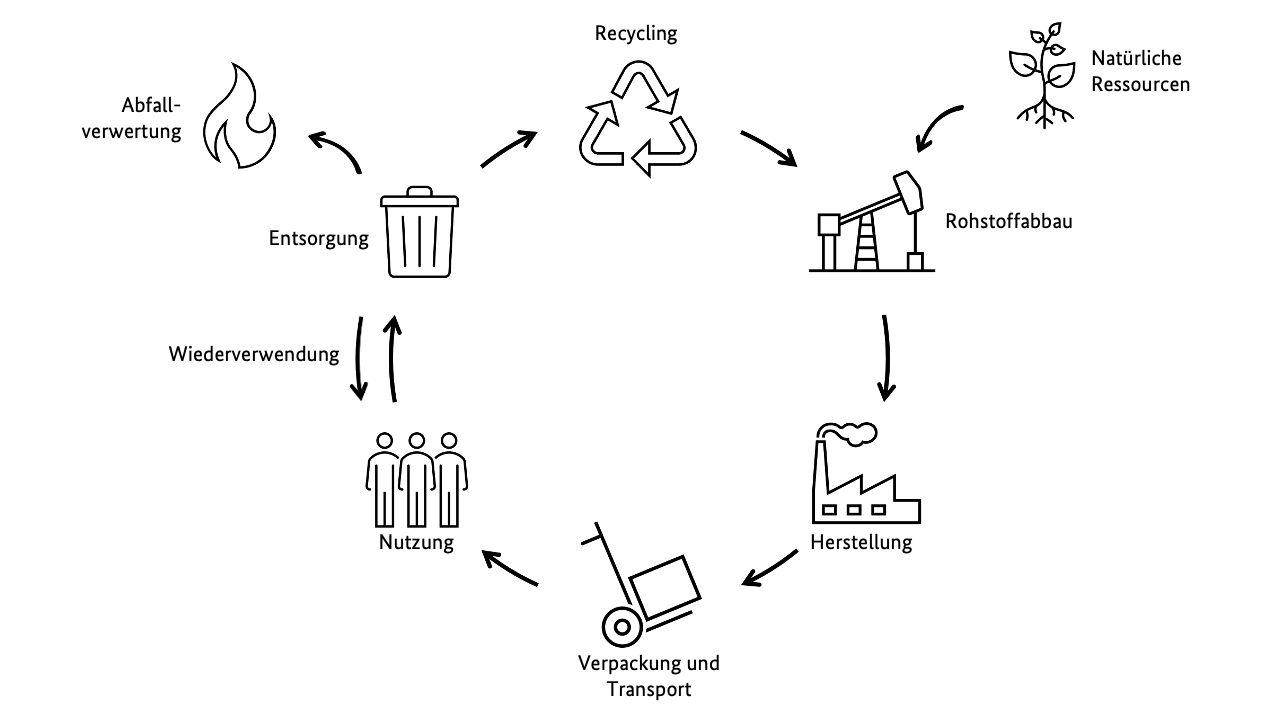

Life cycle assessment (LCA) is a method used to examine the overall environmental impact of a product throughout its entire life cycle. This means that all stages a product goes through are taken into account: raw material extraction, manufacturing and processing, transport and sale, use by consumers, and finally disposal or recycling. This assessment therefore covers not only the direct production of a product, but also all upstream and downstream processes associated with its manufacture and consumption. This reveals the entire context of a product's life cycle by examining how much energy and raw materials are required in each phase and what pollutants are released in the process.

The first step in setting up a life cycle analysis is to define a clear set of objectives: what exactly is to be examined and what are the system boundaries? This is followed by the life cycle inventory, in which all relevant data on materials, energy flows and emissions in the product's life cycle are collected. Then comes the impact assessment, in which the collected data is translated into environmental impacts – for example, how much CO2 is released and how this affects climate change. The evaluation concludes the analysis by interpreting the results and deriving recommendations for action. These can provide information on how to reduce resource consumption and lessen environmental impacts.

Life cycle analysis differs from material flow analysis. While life cycle analysis considers the entire life cycle of a product from start to finish from a bottom-up perspective and focuses on environmental impacts, material flow analysis takes a top-down perspective. It focuses more on how materials and energy move within an entire system and less on the specific environmental impacts that arise. It analyses material and energy flows at a higher level, such as in a factory or an entire industry, and is less detailed when it comes to the specific impacts of individual products.

Page 2 of 6

Why are life cycle assessments necessary?

Life cycle assessments serve several purposes:

- The main objective of LCAs is to identify and minimise environmental impacts, particularly those caused by climate change and other ecological challenges such as acidification, eutrophication and ozone depletion. LCAs reveal where climate-relevant greenhouse gases and other pollutants are released along the entire value chain – from raw material extraction to disposal. This information is crucial for taking targeted countermeasures.

- LCAs contribute significantly to optimising resource efficiency by analysing the use of primary raw materials and energy. They make it possible to identify energy- and material-intensive production steps and find alternatives that consume fewer resources. These savings conserve natural resources and promote sustainable production methods in the long term.

- In addition to ecological factors, an LCA provides insights into social and economic impacts along the entire value chain. In rural areas, for example, the use of natural resources influences economic stability and can create or secure jobs. An LCA therefore gives info not only on the environmental sustainability of a product, but also on its social sustainability, and helps to understand its value creation potential in a differentiated way.

- LCAs provide clarity on complex process chains and help to identify interactions between individual production steps. This helps to avoid shifting problems – for example, measures that reduce environmental impact in one step but increase it elsewhere. An LCA thus helps to develop holistically sustainable processes through optimisation in the right areas.

- Another advantage is the comparison of environmental performance between different products or processes. This allows manufacturers to see which alternatives are less harmful and take targeted measures to improve their environmental balance.

- LCAs also serve as a controlling instrument, as they provide a quantitative basis for pursuing and implementing environmental goals in companies. The analysis provides a detailed overview that is essential for strategic decisions in environmental management.

- Finally, the results of LCAs are a valuable basis for the development of legal standards and guidelines. They support policy makers in developing and implementing scientifically sound measures for environmental protection and resource conservation that promote ecological sustainability and contribute to the achievement of international climate protection goals.

Conflicting goals between climate protection and raw material recovery

A life cycle assessment (LCA) may reveal a conflict of objectives between climate protection and raw material recovery. Raw material recovery – for example, through recycling processes or the reprocessing of waste materials – often requires additional energy to clean, separate and process materials. These processes generate emissions that increase CO2 emissions and thus the carbon footprint. Although raw material recovery conserves primary resources and reduces environmental impact in the long term, the additional energy consumption contradicts the goal of climate protection. Resolving this conflict of objectives between resource-saving recovery and climate-friendly energy conservation is a key challenge in optimising sustainability in a life cycle assessment.

Page 3 of 6

Standards, frameworks and indicators: How LCAs are structured

Although there are numerous different methods for life cycle assessments, their basic structure is defined by standards. ISO standards 14040 and 14044 set internationally recognised standards for implementation and ensure a uniform and transparent approach. They are central guidelines that define how an LCA should be structured, carried out and documented so that results are reliable and comparable.

- ISO 14040 provides a general overview of the structure and principles of life cycle assessment. It describes the essential steps: definition of the objective framework, life cycle inventory (data collection), impact assessment (conversion of data into environmental impacts) and evaluation. The aim of this standard is to establish basic requirements that ensure that each LCA is clearly defined and carried out in a traceable manner in all phases.

- ISO 14044 supplements ISO 14040 and contains more detailed requirements for the methodological implementation of the individual LCA steps. It specifies the requirements for data collection, the calculation rules and the criteria for selecting and evaluating environmental impacts. ISO 14044 also deals with requirements for reporting and interpreting the results.

Although life cycle analyses usually consider the entire product life cycle with all upstream and downstream processes, the scope of the analysis – the system boundaries – can also vary:

- Cradle-to-gate: This considers the life cycle from raw material extraction (‘cradle’) to the manufacturer's factory gate (‘gate’). This analysis therefore ends before the product leaves the manufacturer and includes all environmental impacts of raw material extraction and production, but not the use or disposal of the product.

- Cradle-to-cradle: This perspective covers the entire life cycle of a product – from raw material extraction to recycling in a closed loop. The aim is to ensure that all materials can be reused at the end of their life so that no waste is produced.

- Gate-to-gate: This approach considers only a single production step or a specific process within a company – from the ‘gate in’ to the ‘gate out’ of a particular manufacturing stage. This analysis therefore focuses on a narrowly defined process phase and helps to optimise individual steps in the production chain.

The result of a life cycle analysis depends heavily on how many and which indicators for environmental impacts are analysed. Their selection is crucial for the significance and accuracy of the analysis, but it also presents several challenges.

Depending on the objective, the focus can be on different environmental aspects. For example, an analysis aimed at reducing CO2 emissions primarily uses global warming potential (GWP) as an indicator. However, if a holistic ecological assessment is desired, many other indicators such as acidification potential, eutrophication or human toxicity must be taken into account. This broad selection can lead to a complex and time-consuming analysis, which increases resources and costs.

In addition, the choice of indicators often poses a methodological problem, as indicators can sometimes only capture certain environmental aspects and do not cover all impacts equally well. Some environmental factors, such as the impact on biodiversity or certain social aspects, are difficult to measure and are often neglected, even though they would be important for a comprehensive sustainability assessment.

Another challenge is data availability and accuracy. Many indicators require specific data that is difficult to access in certain industries or regions. This can lead to only those indicators for which sufficient data is available being used, which can limit the significance of the analysis. In the case of complex products with international supply chains, some environmental impacts, such as emissions or water consumption, can also vary greatly across different stages, making it difficult to select the right indicators and evaluate them comprehensively.

Finally, the target audience of the LCA also plays a role. For certain stakeholders, such as policy makers or companies, some indicators are more important than others, but this can lead to a less comprehensive view.

Digital product passport

A digital product passport stores and shares relevant data about a product, including environmental indicators and LCA results, in a digital format. These passports make environmental information accessible to consumers, businesses and authorities throughout the entire value chain. This makes it easier to make informed decisions, favour sustainable products and support processes such as recycling and repair.

Page 4 of 6

Life cycle assessments for the bioeconomy

A life cycle assessment in the context of bio-based products presents specific challenges and special features that go beyond the classic LCA and must take particular environmental aspects into account.

- One key aspect is land use. Bio-based products require agricultural or forestry land. This land use can lead to competition with food production and have important ecological impacts, such as changes in soil health and structure. Land use therefore requires careful consideration in the LCA in order to realistically assess the impact on the environment and the local population.

- Biodiversity is another important factor in the LCA of bio-based products. The cultivation of raw materials for bio-based products such as maize, sugar cane or cotton can affect natural habitats and threaten biodiversity, especially in the case of large-scale monoculture cultivation. An LCA in a bio-based context should therefore include the effects on biodiversity and assess, for example, the loss of species diversity and the impact on local ecosystems. These effects can be reduced by measures such as mixed cropping or agroforestry systems, which in turn can be made transparent through LCA.

- Another unique selling point is the integration of material cycles. Since bio-based products come from renewable sources, they can theoretically circulate in natural cycles. Most bio-based materials are biodegradable and can potentially be returned to the environment, which distinguishes them from non-degradable fossil-based materials. An LCA therefore examines whether and how well bio-based products can be integrated into natural material cycles – for example, through composting or recycling. This makes it possible to assess whether a product can be returned to the environment at the end of its life cycle without leaving behind any pollutants.

LCA as a tool for bioeconomy monitoring

The SYMOBIO 2.0 research project, funded by the Federal Ministry of Education and Research (BMBF), is developing scientific principles for systemic monitoring and modelling of the bioeconomy in Germany. The researchers are also taking sustainability aspects at the international level into account. The development of the monitoring system is framed by the UN Sustainable Development Goals and a systemic approach.

Data from various areas of the bioeconomy is collected and analysed in SYMOBIO 2.0 in order to assess the impact of bio-based products and processes on the environment and resource consumption. LCAs are used to carry out comprehensive environmental assessments for specific products and processes in the bio-based sector.

SYMOBIO 2.0 integrates specific aspects of the bioeconomy, such as land use, biodiversity and resource conservation through renewable materials, into its LCAs. In doing so, the project creates a basis for the systemic assessment of the bioeconomy and shows where the use of bio-based raw materials has positive effects and where potential challenges lie.

In addition, SYMOBIO 2.0 supports the development of indicators and monitoring tools for the sustainable bioeconomy. The results of the LCAs are incorporated into these indicators, which in turn are incorporated into the reporting and evaluation of the National Bioeconomy Strategy. The project has also resulted in the SYMOBIO Data Explorer, an online tool that displays ecological footprints for the German bioeconomy. The Monitoring Bioeconomy information portal brings together all information on bioeconomy monitoring.

Data sources and tools

- ecoinvent: A comprehensive and globally recognised database containing life cycle data for a wide range of materials and processes, including many bio-based materials and production steps.

- Agri-footprint: Developed specifically for agriculture and food production, Agri-footprint provides detailed LCA data for agricultural raw materials used in bio-based products.

- Sphera: A widely used LCA software tool with an extensive database covering a wide range of industrial sectors, including specific data on bio-based raw materials and products.

- EPLCA: Developed by the EU Joint Research Centre, this tool provides a tailor-made database for LCA analyses of bio-based products and materials in the European context.

- USDA LCA Commons: A database operated by the US Department of Agriculture that focuses on life cycle data for agricultural products and bio-based materials and provides a valuable resource for US-specific data.

- EXIOBASE: An input-output database that provides comprehensive information on global material flows and environmental impacts for numerous regions.

- openLCA: A free, open-source LCA tool that provides access to various LCA databases and is suitable for LCAs in the bio-based sector, especially for beginners.

Page 5 of 6

Concepts of sustainable product development

Various approaches have established themselves on the path to sustainable product development.

Eco-design uses the results of a life cycle assessment to design the entire life cycle of a product sustainably right from the planning phase. LCAs identify the phases that are particularly environmentally intensive – such as raw material extraction, manufacturing or use. Based on these findings, eco-design selects materials and processes that consume fewer resources and energy and reduce waste. For example, an LCA could show that a certain plastic causes high CO₂ emissions during production. In the eco-design process, this plastic would then be replaced by a more environmentally friendly alternative in order to reduce the environmental impact.

Circular design is based on the principle of the circular economy and aims to design products in such a way that they can be recycled, reused or repaired after use. An LCA helps to highlight the environmental benefits of closed loops by comparing a linear model (raw material – product – waste) with a circular model. LCAs show how much material and energy can be saved when products and materials remain in the cycle. Circular design uses these findings to develop products that are durable, modular and can be recycled as completely as possible at the end of their useful life.

Life-cycle thinking is the overarching concept that considers the entire life cycle of a product – from raw material extraction to disposal – as the basis for all decisions. This is not just about individual measures, but about a holistic perspective that is necessary for the development of sustainable products. Life-cycle analyses are the central tool of this approach, as they reveal the environmental impact of each phase. Life-cycle thinking ensures that decisions at each stage are based on minimising the environmental impact of the product throughout its entire life cycle.

Page 6 of 6

Practical examples: LCAs for bioeconomy products

There are numerous assessment methods used in LCAs. These include the ABC method (which prioritises processes and materials into classes A, B and C depending on the size of their environmental impact), the CML method (developed by the Centrum voor Milieukunde in Leiden), the carbon footprint, Eco-Indicator 99, the Environmental Priority System (EPS), cumulative energy expenditure (KEA), the MIPS concept (material input per service unit) and the Sustainable Process Index (SPI). Due to space constraints, these methods cannot be described in detail in this dossier. Instead, this chapter highlights practical examples of LCA for products and processes that are relevant to the bio-based economy.

Life cycle of a T-shirt

The Technical University of Berlin has conducted a life cycle assessment for a white cotton T-shirt. The aim of the study was to record and evaluate the environmental impact across production, use (especially laundry care) and disposal. The researchers focused on the most significant environmental impacts during use, particularly the effects of washing on energy and water consumption.

In the course of the study, the researchers compiled a detailed life cycle inventory documenting all relevant inputs and outputs during the life cycle of the T-shirt. They also carried out an impact assessment, quantifying the various environmental impacts in categories such as global warming potential, acidification potential, eutrophication and water consumption.

The results show that manufacturing, and cotton production in particular, caused the greatest environmental impact. Laundry care in the home, especially the energy consumption of washing machines, also represented a significant burden. Sensitivity analyses of the washing parameters showed that reducing the washing temperature can significantly reduce the environmental impact.

How mulch films affect the environment

The life cycle analysis in Fraunhofer UMSICHT's iMulch project examined the environmental impact of various mulch films used in strawberry cultivation. The aim was to assess the overall environmental impact of these films, from production and use to disposal, with a particular focus on microplastics and plastic pollution.

The researchers chose the Product Environmental Footprint model as the basis for their impact assessment. They also incorporated a method that takes into account the environmental impact of plastic emissions. The researchers analysed various scenarios for mulch films: conventional films, biodegradable films and films made from different polymers, in combination with additional protective measures such as tunnel covers. The experts then carried out a comprehensive life cycle inventory, using data from the ecoinvent database (see Data sources and tools in Chapter 4). The functional unit of the analysis was one kilogram of marketable strawberries. Specific parameters such as fertiliser and irrigation requirements for different cultivation scenarios were adjusted in the model. The scenarios were evaluated by normalising, weighting and aggregating the environmental impacts, enabling a uniform environmental assessment of each scenario.

The results showed that biodegradable mulch films could reduce environmental impacts compared to conventional films, particularly through lower persistence in the soil. However, some cultivation systems cause high environmental impacts despite high productivity, such as the use of macro tunnels or greenhouses.

Life cycles of fishing nets and biolubricants

In the SEARCULAR project, researchers from Fraunhofer UMSICHT and other institutions are investigating the environmental and sustainability impacts of fishing equipment such as nets, which often end up as plastic waste in the oceans. The LCA is used to assess the environmental impact of various solutions for more durable and environmentally friendly fishing equipment. Among other things, recycled nets, biodegradable ropes and ports with improved recycling facilities are being tested. The results are expected to be available at the end of 2026. However, the interim results already suggest that biodegradable materials and sustainable port management can reduce plastic pollution and promote sustainability in fisheries.

In the PHAtiCuS project, researchers are conducting a life cycle assessment for the bio-based lubricants they have developed, which are based on polyhydroxyalkanoates (PHAs) and do not contain any per- and polyfluoroalkyl substances (PFAS) that are harmful to the environment and health. The LCA assesses the environmental impact of PHA-based lubricant products throughout their entire life cycle – from fermentation and production to application and biodegradation. The aim is to compare the environmental performance of these bio-based products with conventional mineral oil-based lubricants and thus highlight their advantages in terms of biodegradability and resource conservation.

The analysis showed that PHA-based lubricants can have a lower environmental impact in terms of carbon footprint and biodegradability, making them a more environmentally friendly alternative to conventional lubricants. However, the research emphasised that the life cycle assessment is highly dependent on factors such as energy consumption during fermentation and the efficiency of the technologies used. Overall, the project highlights the potential of these bio-based lubricants, particularly in areas where biodegradation and resource conservation are crucial.

Carbohydrates from press residues from apple juice production

At Fraunhofer IWKS, the GlyPac project uses innovative extraction methods to obtain glycans from apple pomace – a by-product of the food industry. At the same time, the eco-design potential of these innovative products, which can be used as binders in coatings, for example, is being demonstrated. With the help of a prospective life cycle analysis, the environmental impacts from raw material procurement to glycan production will be quantified by summer 2025. The analysis covers the phases from the extraction of glycan polymers using a chemical-free hot water method to processing and application in packaging materials. Both the environmental performance on a laboratory scale and in a potential large-scale implementation will be evaluated. Particular attention will be paid to analysing whether bio-based polymers can (partially) replace fossil raw materials in printing inks and coatings on packaging without placing an excessive burden on the environment.

The results so far show opportunities for early eco-design, which can achieve significant reductions in environmental impact.

Biomethane under scrutiny

The International Council on Clean Transportation (ICCT) conducts life cycle assessments to evaluate renewable fuels in relation to the minimum greenhouse gas reductions required under the Renewable Energy Directive (RED II). The studies, which focus on biomethane and hydrogen as fuels, analyse the entire life cycle of the fuels – from raw material extraction to end use – to ensure that they meet the RED II requirements, which stipulate a reduction in greenhouse gas emissions of at least 70 per cent compared to fossil fuel benchmarks. The LCA results show that both biomethane from waste sources such as sewage sludge and landfill gas, and hydrogen produced using renewable energy, generally meet or exceed the minimum greenhouse gas savings requirements. Biomethane can even have negative net emissions when produced through processes such as anaerobic digestion with waste recovery. Hydrogen produced by electrolysis using renewable electricity also achieves high savings, but only if the electricity comes from additional sustainable sources.