Detecting wood species in fibre materials with AI

Together with the Thünen Institute, Fraunhofer researchers are developing AI-based software for the microscopic identification of wood species. The aim is to ensure that timber products originate from legal trade.

Whether chipboard, furniture or paper: since June last year, anyone wishing to place a wood product on the market in the European Union (EU) has had to prove that the types of wood used come from legal trade. Traders must document the type of wood and country of origin. With the ‘European Deforestation Regulation’, the EU aims to minimise the risk that the extraction of timber contributes to deforestation, damages the ecosystem through deforestation or even displaces people.

Determining wood species with AI

In order to detect and avoid violations of the law, the Thünen Institute carries out appropriate checks, which are, however, very time-consuming. This is set to change: Researchers at the Fraunhofer Institute for Industrial Mathematics (ITWM) in Kaiserslautern are working with the Thünen Institute of Wood Research in Hamburg to develop AI-supported analysis software that will speed up and automate the inspection process, enabling fast and efficient inspections.

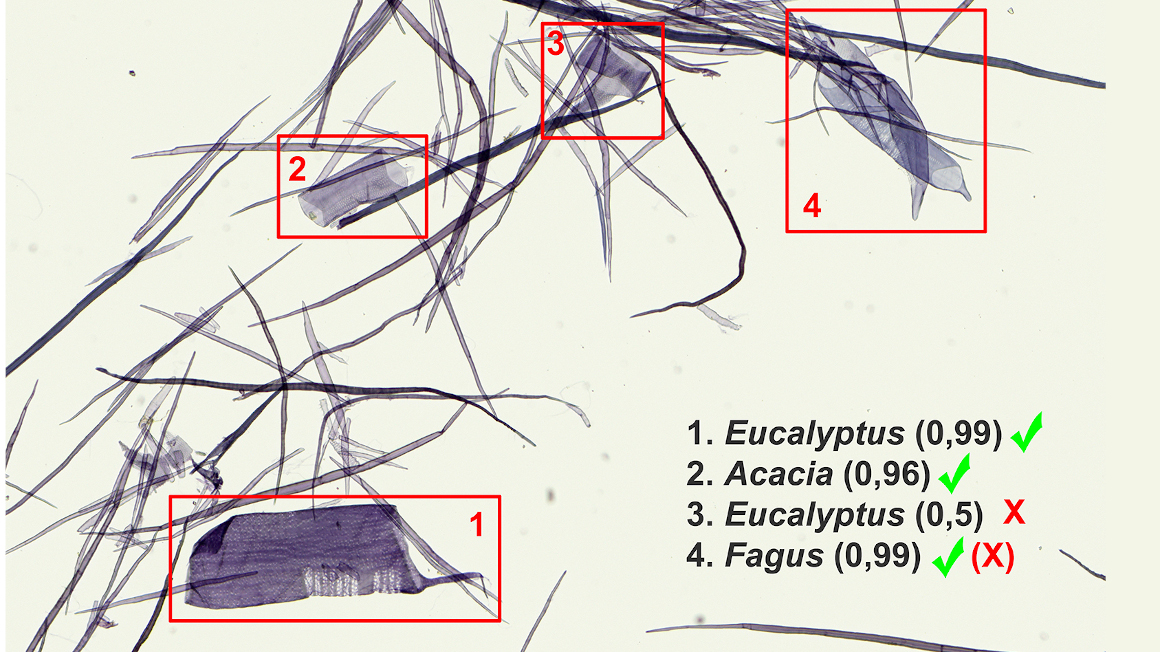

Until now, wood species have been tested using fibre materials. To do this, wood cells are removed from products such as paper and fibreboard, stained and prepared on a microscope slide. Only under the microscope can the cells be classified on the basis of their appearance.

The ‘KI_Wood-ID’ project, funded by the Federal Ministry of Food and Agriculture (BMEL), is now developing a new automated image recognition system for wood species identification using machine learning. As the vascular cells of the wood differ in structure, shape and size, the type of wood can be clearly determined with the help of artificial intelligence. The AI needs to be trained for this.

AI training with hardwoods

The project is initially focussing on hardwoods, especially plantation woods, which are cultivated worldwide for pulp production. Here, the researchers can draw on reference specimens from the wood collection at the Thünen Institute. According to the researchers, the neural networks are trained with the references until the AI is able to independently identify and classify the characteristic features of the wood species and thus detect the wood species contained in the microscopic image of an unknown sample. The AI must therefore complete the training individually for each type of wood, such as birch, beech or poplar. ‘The sample is conspicuous if it contains characteristics that do not match the declared wood species,’ explains Henrike Stephani, head of the KI_Wood-ID project at Fraunhofer ITWM.

Supporting the international timber trade

An initial prototype of the analysis system already exists and is able to recognise eleven hardwoods. Next, the researchers want to focus on the identification of softwoods. In the long term, the AI-based image recognition software will not only be available to the Thünen Institute, but will also support testing laboratories and authorities worldwide in monitoring the international timber trade. ‘Ultimately, deforestation and the illegal timber trade can only be prevented at a global level, which is why we hope that globally approved testing organisations will benefit from our system in the future,’ says the researcher.

With the help of the AI software, the team not only wants to strengthen the legal timber trade and thus protect consumers. According to the project manager, the identification of protected wood species in pulp such as Ramin could also ‘hold manufacturers to account’.

bb