New perspectives for the textile industry

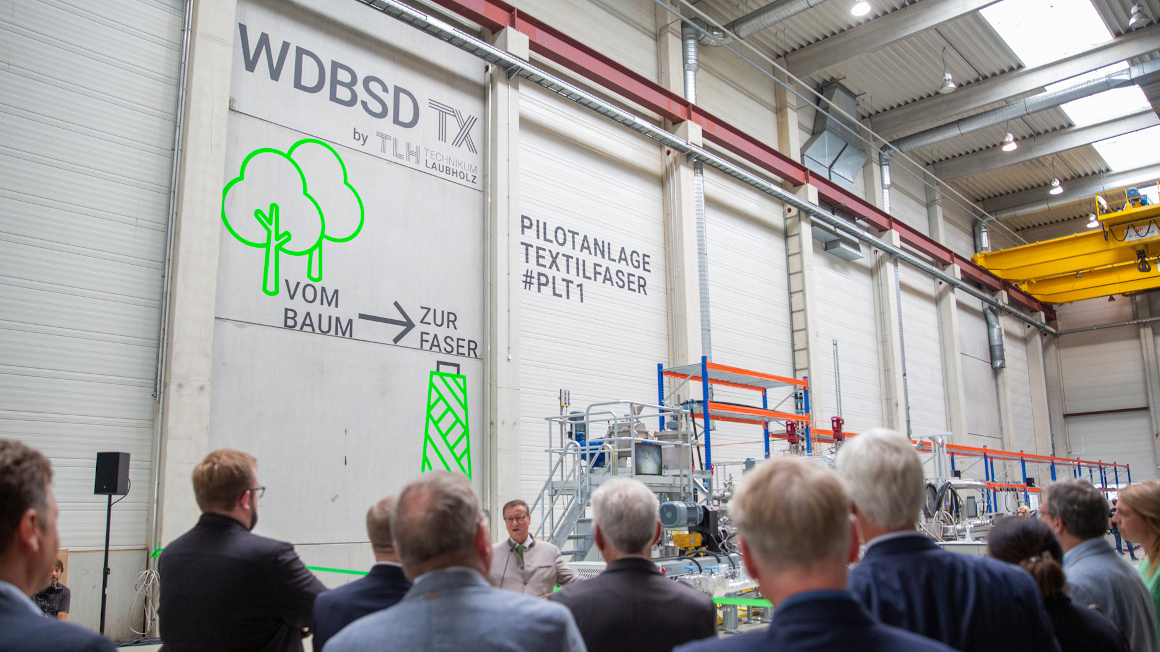

A pilot plant for the production of high-performance fibers from beech pulp went into operation at the Technikum Laubholz in Göppingen.

The fashion industry is responsible for 5% of global CO2 emissions. Water consumption and pollution from dyeing, as well as textile waste after use, also pollute the environment. But the textile industry is changing - not least because customers increasingly value sustainably and fairly produced clothing.

One alternative to cotton is wood. With the opening of the new pilot plant for the production of textile fibers from beech wood, the Technikum Laubholz (TLH) in Göppingen aims to drive the textile industry's turn towards sustainability.

Innovative wood pulping process

The wet-spinning plant inaugurated at the beginning of August produces the textile fiber "Woodbased Textile Fiber – WDBSD TX" obtained from beech pulp. This is an innovative high-performance fiber obtained by a novel, already patented wood pulping process. "With the new pilot plant for the production of textile fibers from domestic beech wood, we are entering innovative new territory and will revolutionize the textile industry," said the Minister for Food, Rural Areas and Consumer Protection, Peter Hauk (MdL), at the inauguration ceremony.

Closed raw material cycle without waste streams

According to the researchers, the process ensures a closed raw material cycle without waste streams. On the one hand, raw materials from regional forestry are used to produce the textile fibers. On the other hand, water and solvents can be reused due to efficient process control and a solvent recycling system. The solvent used is an ionic substance that is non-toxic, ecologically harmless and 100% recyclable.

Contribution to sustainability and environmental protection

"It is inspiring to see the transformative impact this sustainable technology will have in different industries. With WDBSD TX, we are not just revolutionizing fibers. We are actively shaping a tangible and more sustainable future," said Rolf Moors, Head of Fiber-based Biopolymer Materials at TLH.

According to the researchers, the textile fibers produced from beech wood can be used in a variety of ways - as technical textiles in the automotive industry, in medicine, for hygiene articles or even for the production of everyday and sports clothing. "We are proud to have developed a groundbreaking technology that will not only revolutionize the textile industry, but also make an important contribution to sustainability and environmental protection," said Ludwig Lehner, managing director of TLH.

The Technikum Laubholz was founded in 2020 by the Ministry of Rural Areas and Consumer Protection Baden-Württemberg. The focus is on the development of innovative and marketable process solutions for hardwood-based products such as carbon fibers from wood.

bb