Molecular structure of lignin uncovered

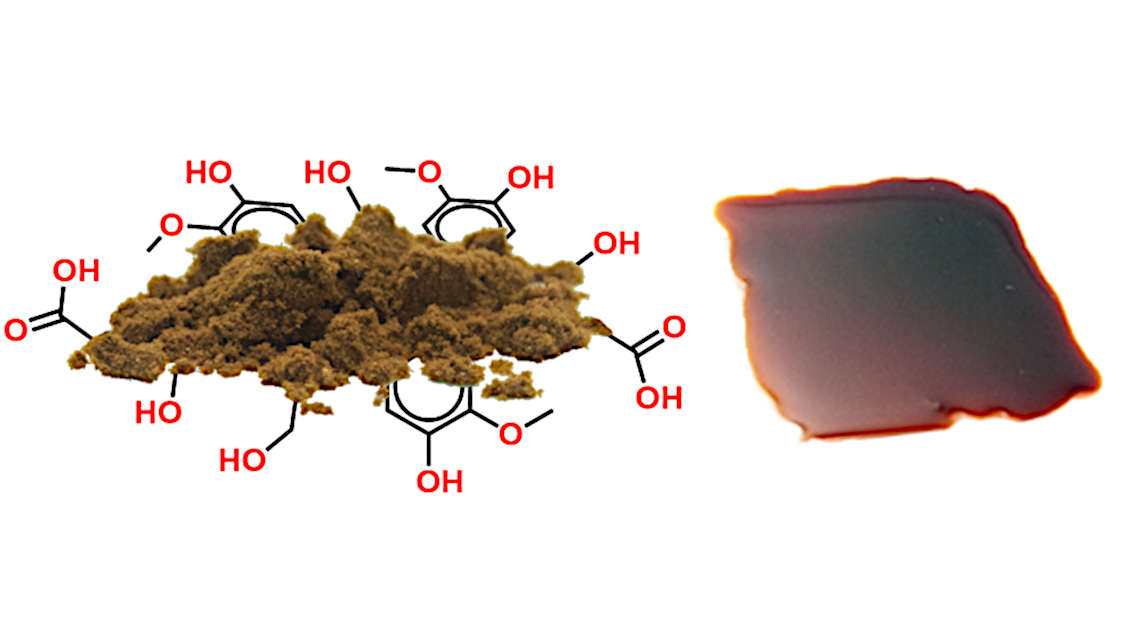

Lignin is an attractive raw material for bioplastics. X-ray analyses have shown how the different molecular structures influence the properties of the biopolymer.

One valuable raw material that has so far mainly been burned is the biopolymer lignin. It is one of the major components of plants and a promising alternative to crude oil for the production of plastics. "Lignin is the largest source of naturally occurring aromatic compounds, but so far it has mainly been regarded as a by-product or fuel in the paper industry," says Mats Johansson of the Royal Institute of Technology (KTH) Stockholm regretfully. "Millions of tons of it are produced every year, which could be available as a continuous stream of feedstock for new products".

Non-uniform molecular structure

There is, however, a good reason why the industry is struggling to use lignin as a material: Like most natural products, there is a certain variability in the structure of the lignin molecules. This leads to different material properties that have so far been difficult to control. X-ray analyses at the German Electron Synchrotron DESY could now change this. In the journal Applied Polymer Materials, the scientists report on differences in the nanostructure of commercially available lignins and how these affect the material properties.

Size and arrangement of the building blocks are crucial

It has been shown that the lignin is sometimes composed of larger and sometimes smaller building blocks, explains lead author Marcus Jawerth of KTH Stockholm. "This has advantages depending on the application: It makes the lignin harder or softer by changing the so-called glass transition temperature at which the biopolymer assumes a viscous state." The arrangement of certain molecular structures in relation to one another also influences how the lignin behaves.

Systematic overview in the pipeline

The researchers are now planning to carry out further investigations in order to gain a systematic overview of how different parameters affect the lignin properties. "This is extremely important in order to produce materials reproducibly and, above all, to predict the material properties," emphasizes DESY researcher Stephan Roth. "If you want to use the material industrially, you have to understand its molecular structure and correlate it with its mechanical properties."

Enormous potential for bioplastics production

Roth estimates that about two thirds of the lignin from paper production, which is currently the most commonly burned lignin, could be used in future as a raw material for the production of plastics. "Together with cellulose and chitin, lignin is one of the most common organic compounds on earth and has enormous potential to replace petroleum-based plastic raw materials," the researcher sums up. It is far too valuable to burn, he argues.

bl/um