Campus for sustainable car manufacture opened

Using high-tech to make tomorrow's environmentally friendly car. That is the goal of the brand new LeichtbauCampus Open Hybrid LabFactory in Wolfsburg. Central government is supplying 30 million euros.

Light vehicles that consume little and are therefore less environmentally problematical – that is how the car of the future should be. The foundation for next-generation-but-one vehicle technology has just been laid in the car manufacturing city of Wolfsburg. In the presence of Federal Minister of Research Johanna Wanka, the LeichtbauCampus Open Hybrid Lab Factory was inaugurated at a location not far from the headquarters of VW. The research factory is a figurehead public-private investment project. The Federal Ministry for Education and Research (BMBF), the State of Lower Saxony, the City of Wolfsburg as well as industrial partners headed by Volkswagen have so far invested about 60 million euros in the construction and equipment of the new four-storey building in the Hermann-Münch-Straße.

200 million euros for lightweight construction research

Building began in December 2014. There are now new offices, laboratories and a technology centre for 200 employees and 150 students covering a total of 5,200 m2. A further 200 million euros are to be invested in research projects at the LeichtbauCampus over the coming 15 years. The BMBF is to supply 30 million euros of that sum as part of the 'Forschungscampus – öffentlich-private Partnerschaft für Innovationen' (Research campus – public-private partnership for innovation') funding initiative. "The research factory is the result of a fruitful cooperation between science and industry that has received acknowledgement far beyond the limits of Wolfsburg itself. This is where the car of the future is being developed," declared Federal Minister of Research Johanna Wanka on the occasion of the campus' official opening on 22 September in Wolfsburg. Wanka went on to say that the research factory would enable faster implementation of new products, techniques and services.

Concentrating competence

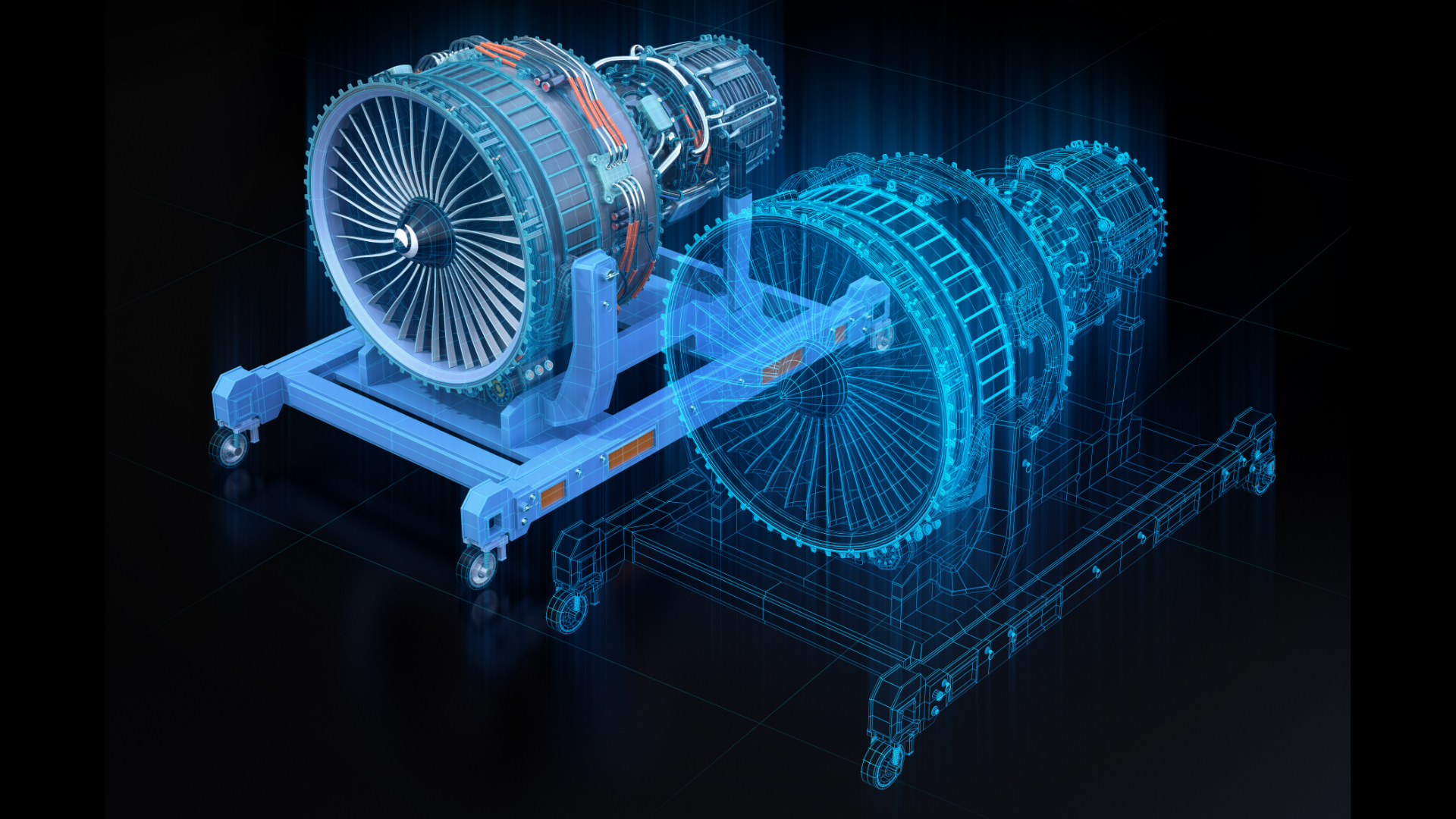

The LeichtbauCampus demonstrates a new type of cooperation between science and industry. This is where experts from universities, research facilities and industry will be able to work together on equal terms and bundle their various areas of competence to pursue research into lightweight construction. Under the aegis of the Automotive Research Centre of the Technical University of Brunswick (Technische Universität Braunschweig), Volkswagen, the Fraunhofer-Gesellschaft as well as seven other internationally active companies and many other project participants will be cooperating under one roof. The Open Hybrid Lab Factory is to be a breeding ground for key technologies for vehicle chassis and drive systems of the coming car generations. These are to be economically viable in series production. "This campus is to set standards in the development of low-emission, safe and nevertheless cheaper vehicles. It is to be a trailblazer for research in the field of vehicular lightweight construction," explained Matthias Müller, Volkswagen's CEO.

Towards a sustainable automotive industry

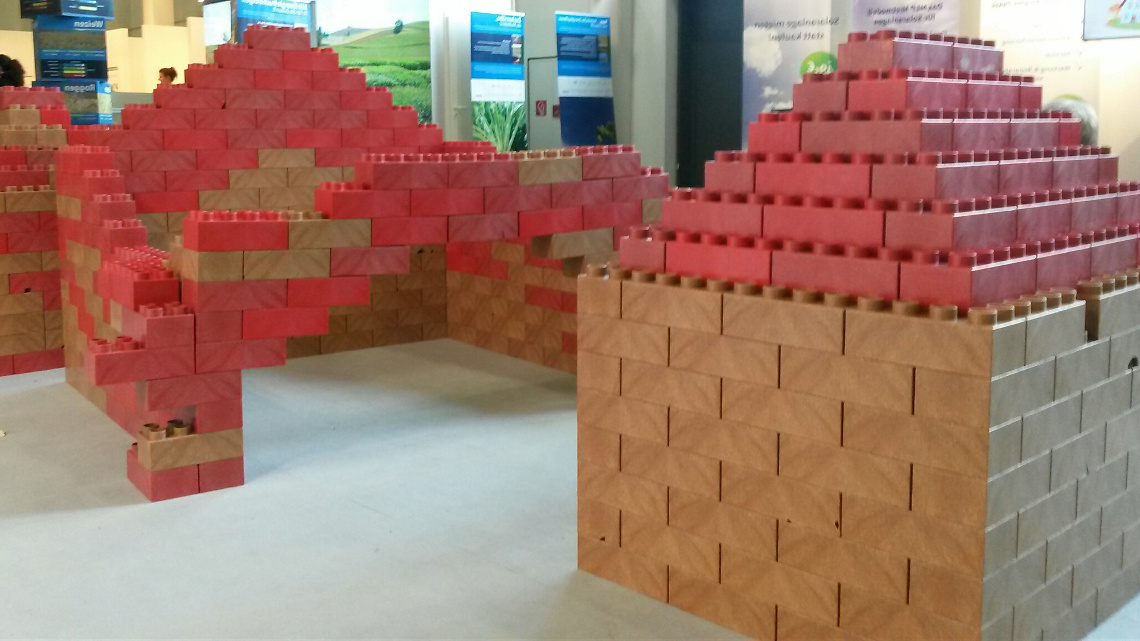

To date, lightweight construction solutions have been expensive and inefficient in their use of resources, so they have remained niche products. The newly opened research campus is to change that. To this end, the partners want to continue development of so-called hybrid design. The entire value-creation chain for hybrid components is to be taken into account, from the earliest design phase to manufacturing, from the manufacturing processes to recycling. The aim is to assemble different materials such as metal, plastic and textile structures into lightweight components in such a way that they can hold their own against conventional cars regarding safety standard and performance. "Lighter, but still safe – those are important parameters on the path to a sustainable automotive industry," emphasized Lower Saxony's Prime Minister Stephan Weil as well.

The research factory will house representatives of three different Fraunhofer institutes: the Institute for Manufacturing Technology and Advanced Materials (IFAM), the Institute for Machine Tools and Forming Technology (IWU) and the Institute for Wood Research Wilhelm-Klauditz-Institut (WKI). They will contribute their competence in the fields of lightweight construction and electromobility. This concentrated know-how is also to be of benefit to students and young researchers.