New plant-based nanofibers

Zoologists in Kiel have discovered highly adhesive cellulose nanofibres in the slimy protective layer of plant seeds, which may be very useful for biomedical applications.

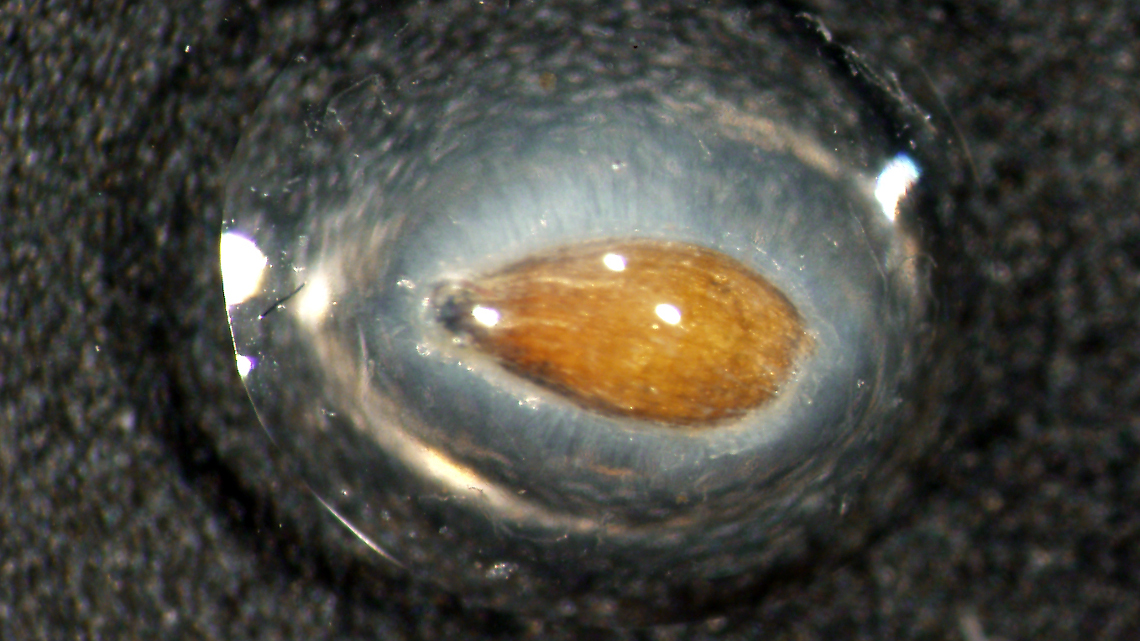

Many plants need animals to eat their fruits in order to spread their seeds. To prevent the seeds from being destroyed during digestion, many of them form a slimy protective shell. This sheath also forms independently of digestion as soon as the seeds come into contact with water. A team of researchers from Kiel University has now discovered that the stability of the mucus membrane depends heavily on tiny fibres that bind the mucus to the seed. The researchers report in the journal "Applied Materials & Interfaces" on these highly adhesive nanofibers, which could in the future be used for biomedical applications.

Gentle dehydration enables view onto tiny cellulose fibres

The protective coating of the seeds mainly consists of cellulose, the major component of plant cell walls, as well as pectins, which are plant sugar molecules. The pectins in the shell of the seeds can absorb large amounts of water in a short period of time, resulting in a gel-like capsule within a few minutes. Miniscule cellulose fibres with a diameter of up to 100 nanometres anchor the capsule firmly to the surface of the seed.

"In order to find out more about the function of the mucilage, we first wanted to study the structure and the physical properties of this seed envelope material," said Stanislav Gorb, Zoology Professor at the Christian Albrechts University of Kiel (CAU). The team around Gorb used a special dehydration method that gently extracts the water from the mucus membrane. The trick: With the help of so-called critical point drying, the mucous membranes were gradually dehydrated via liquid carbon dioxide. This can be evaporated in a controlled manner under certain pressure and temperature conditions, without a surface tension forming in the shell. Thereby preserving the original cell structure and individual cellulose fibres.

Cellulose fibres demonstrate excellent frictional and adhesive forces

Subsequently, the researchers investigated the friction and adhesive properties of the fibres. "Our tests showed that the frictional and adhesive forces of the cellulose fibers are almost as strong as with vertically-arranged carbon nanotubes," said Clemens Schaber, first author of the study. Carbon nanotubes are microscopic in size and are popular in industry and research for their outstanding electrical conductivity, tear strength and friction properties.

Due to this dehydration process, the research group was also able to vary the adhesive strength of the cellulose fibers in a targeted manner. "As a natural raw material, cellulose fibers have distinct advantages over carbon nanotubes, whose health effects have not yet been fully investigated," continued Schaber. Nanocellulose is mainly used for biodegradable plastic composites, which in turn are applied in biomedicine, cosmetics and the food industry.

jmr