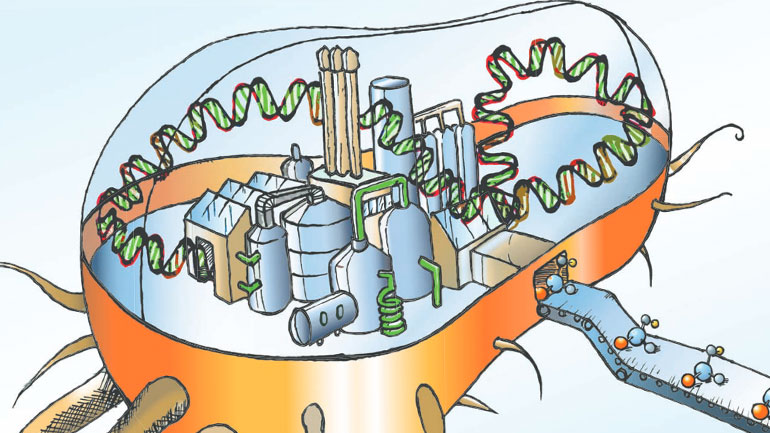

Biotechnology involves reaction processes that, due to enzymes, take place under much milder and thus more energy-saving conditions than classical synthesis chemistry. Biotechnology means precise reactions without problematic waste products. And biotechnology means using climate-friendly biogenic raw materials - mostly sugars or alcohols - instead of fossil raw materials. But sugars and alcohols are usually expensive, and they often compete with food or feed production. The SynHydro3 project therefore aims to supply novel biotechnological processes with hydrogen as an electron source instead of sugar. The German Federal Ministry of Education and Research is providing slightly more than one million euros in funding for this until September 2024.

More efficient than sugar or alcohols

"Carbon-containing molecules such as sugars or alcohols are neither energy- nor atom-efficient when used as electron donors," explains Nicolas Plumeré of the Technical University of Munich. They are used by default, but mean a compromise solution, forced by the requirements of the catalysts and the reaction conditions. Hydrogen has not been an option so far, since the enzyme hydrogenase is the corresponding biocatalyst for its use. Hydrogenases are extremely sensitive to oxygen and irreversibly stop working when they come into contact with oxygen.

So how did the research team, which includes the TU Munich, the Fraunhofer Institute for Interfacial Engineering and Biotechnology, the Max Planck Institute for Chemical Energy Conversion and the company ESy-Labs from Regensburg, come up with the idea of using hydrogen in biotechnology in the first place? "Our research comes from electrochemistry, that is, the field of fuel cells and electrolyzers for hydrogen production, where platinum and other precious metals are usually used as catalysts," reports the electrobiotechnologist. "But precious metals are not infinitely scalable because their available quantities are limited. Hydrogenases fill this gap and can solve the scaling problems." In fact, their activity as catalysts is similar to that of precious metals; they just aren't as robust in natural form.

A protective matrix for the sensitive enzyme

"In the near future, it will not be possible to make the enzyme itself more robust," Plumeré believes. "We therefore protect it by embedding it in a film of redox-active polymers on the electrode." This allows the hydrogenases to oxidize hydrogen and provide electrons for subsequent reactions without reacting with oxygen and thereby becoming inactivated. In electrochemistry, Plumeré's team has already shown that it is possible to protect the enzyme using this chemical trick. The researchers now want to transfer and expand this concept, making it accessible to a novel biotechnological process.

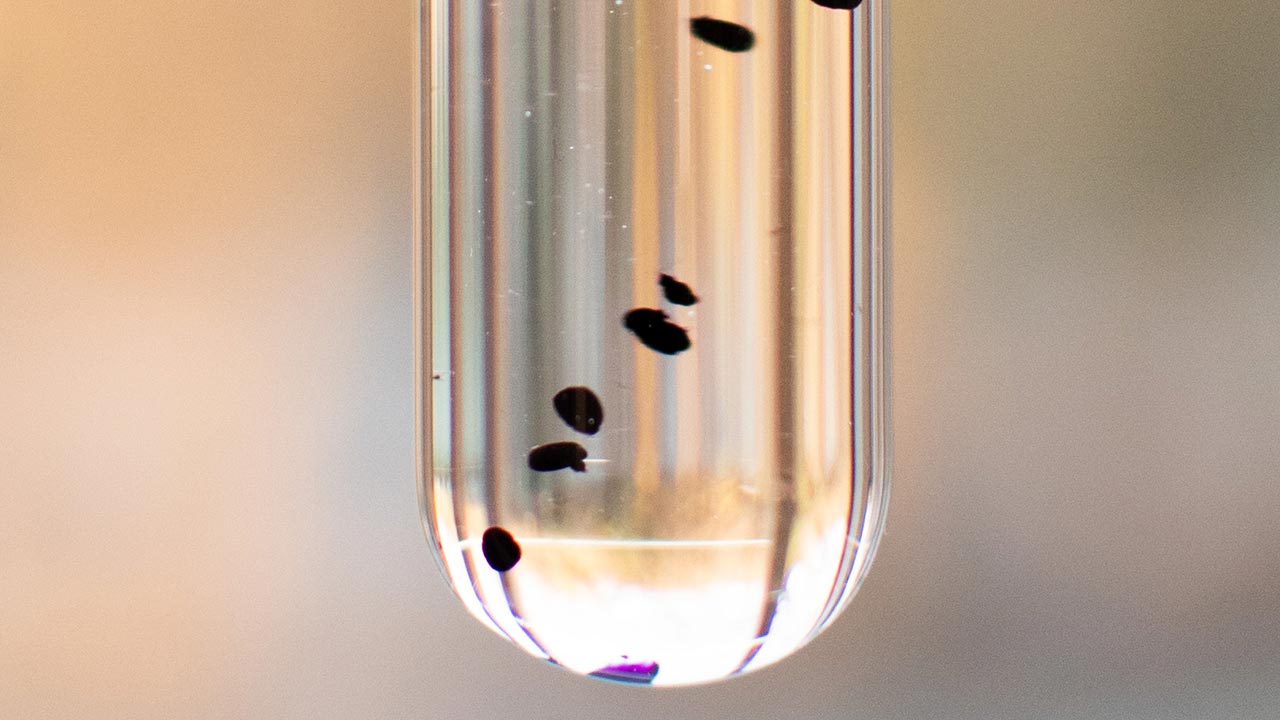

For electrodes, the approach worked by applying a few micrometers thin film of polymers to the electrode surface. The enzymes are immobilized in this protective film. "For biotechnological synthesis processes, however, we need to have the hybrid material in a suspension in the reaction solution in the bioreactor," explains Plumeré. Millions of thin, floating microdisks processed according to the principle described above are expected to be the solution. A certain size is required so that substances can diffuse into the catalytically active material. At the same time, the disks must be thin enough so that there is no substrate limitation.

Searching for the right structure

A major challenge is to immobilize the hydrogenase - and all the other enzymes of the respective biotechnological production cascade - in functional form on this disc. "We need a structurally stable polymer structure that enables crosslinking without inactivating the enzymes," says the project leader. In biochemistry, crosslinking is the linking of molecules to form three-dimensional structures. On the surface of an electrode, the layer thickness can be easily controlled. However, when they float freely, the slices must not clump together or disintegrate. If successful, existing bioreactors should be able to continue to be used in industry and only need to supply hydrogen.

The project has been running for a year. "We are looking for the perfect material to produce the discs easily," explains Plumeré. The discs are printed on low-adhesion surfaces such as Teflon. At completion, the discs would be easily released from the surface in a roll-to-roll process. Both steps would be easy to scale.

The feasibility is proven

The researchers have already been able to show that the disk concept basically works in biotechnology. They have immobilized hydrogenases together with an enzyme that can regenerate the biochemical energy carrier NADPH - i.e. in a sense recharge it with electrons - in these disks. They then succeeded in regenerating NADPH using hydrogen.

The team was pleasantly surprised by how easy it was to scale up the production of a selected hydrogenase. "We generate the protein shell of the enzyme biologically and the active site with metals chemically. If we bring both into an aqueous solution, the active site spontaneously gets into the right place in the protein shell and the enzyme is thus functional," the researcher reports. Although this mechanism was basically known, this is how they found out that it would also work smoothly on this large scale.

Now the acid test is on

The next step will be the most difficult: Now it all has to work for a reaction that is oxygen-dependent. "We are planning a hydroxylation as a model reaction," says Plumeré. That's a classic biotechnology reaction, only usually with sugar or alcohol as the electron donor. "But it would be cheapest with hydrogen," the researcher emphasizes.

"Once we get the oxygen-dependent reaction right, virtually any reaction is possible with this system," says the project leader, describing the enormous potential for using SynHydro3 technology to drive many classic reactions in biotechnology. This is because, in principle, all types of enzymes can be anchored in the polymer disk without having to modify or further develop the disk. The researchers have already tested this for some enzymes. If the process is successfully commercialized - and the project participants hope it will be - customers could supply their enzymes and production could be virtually "on demand.

The project goal is long-chain carbon molecules

"In this context, we are interested in all reactions in which CO2 is incorporated into molecules, because electrons and protons are needed to synthesize complex molecules," says Plumeré. Anything is possible, he says, from bulk chemicals to fine chemicals. The project team itself would like to be able to produce long-chain carbon molecules by the end of the project. Compared to the established process, production with hydrogen could become completely fossil-free.

And for those who wonder where all the hydrogen will come from in the event of success: The chemical industry already consumes large quantities of gray hydrogen for ammonia synthesis in fertilizer production alone. According to Plumeré's assessment, the hydrogen for the new reaction process would not make any further difference - and should also be green, i.e., come from renewable sources.

Author: Björn Lohmann