Bio-based food wrappings

Partners from research and industry want to develop multilayer packaging materials based on chitosan and at the same time work out a corresponding method for quality control.

Plastic films account for a large proportion of packaging waste, including in the food sector. Sustainable alternatives face the challenge of having to meet numerous requirements for a packaging material. The Fraunhofer Institute for Microstructures of Materials and Systems (IMWS) in Halle (Saale) is therefore conducting research on bio-based multilayer films for food products in cooperation with the film specialist Polifilm Extrusion from Weißandt-Gölzau.

Diverse requirements

Packaging films not only have the task of being tear-resistant to protect the food from dirt and to present printed or glued information to the customer. They have to keep aroma and taste substances inside by means of so-called migration barriers and prevent microorganisms from penetrating. In this way, they guarantee freshness and shelf life. Films often meet these versatile requirements by being designed as multi-layer systems consisting of the plastics polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET) and polyvinyl chloride (PVC).

Both the packaging waste problem and the climate crisis have for some time been placing further demands on food films: they should be produced sustainably and be biodegradable or easily recyclable. The Packaging Act, which came into force in 2019, aims to improve the recycling rate of plastic packaging from 36% at present to 63% in the future.

Barrier effect and mechanical stability

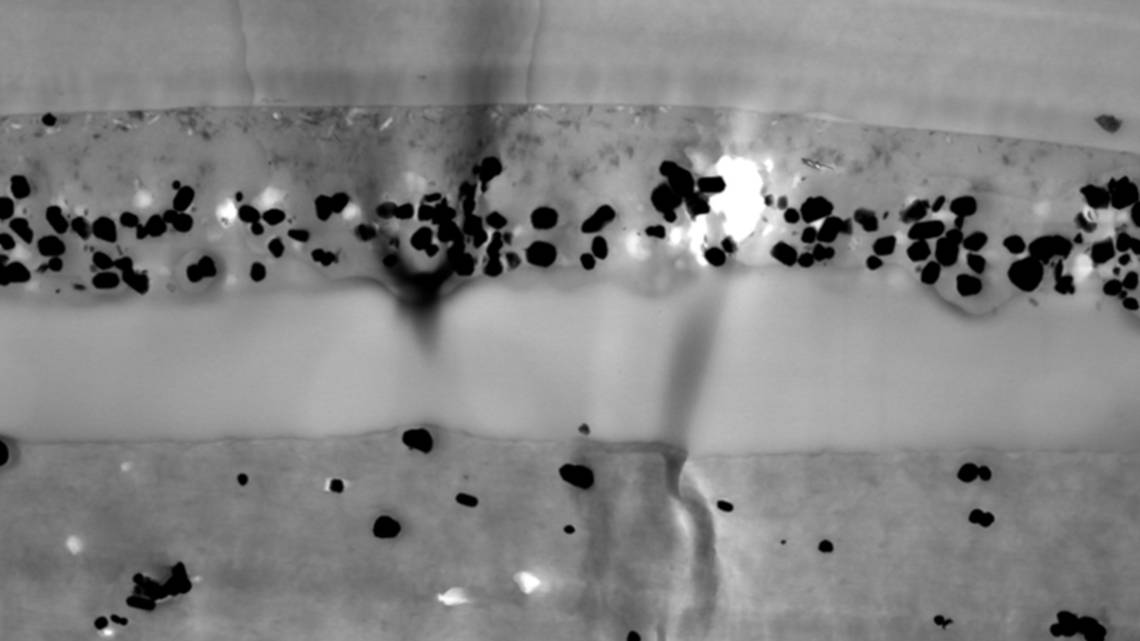

The two research partners have set themselves the goal of developing sustainable food films by August 2021: "We intend to engineer a multilayer film made of biopolymers that is an efficient barrier, but is also very mechanically stable, sufficiently transparent, and equipped with further properties important to its further use," explains Sandra Richter, project manager at the Fraunhofer IMWS. The basis for this will be clever combinations of biopolymers and fillers. The biopolymer chitosan, which is obtained from the shells of crustaceans, is central to this process. "Apart from its antibacterial effect, chitosan is highly biocompatible, biodegradable, non-toxic, and acts as a natural barrier as well," explains Richter.

Industrial process with quality control

However, the research project does not only focus on the development of appropriate multilayer films. It also aims to develop an industrial process that can be used to produce the food films on a large scale. Last but not least, the project partners are researching a method of non-destructive quality assurance. This method is intended to detect any compound defects, inclusions and the like in the manufacturing process and ensure that the films meet all the requirements of an industrial product.

bl/um