Turning organic waste into fuel

Using zeolite catalysts, Munich-based chemists have managed to reduce temperature and energy requirements to efficiently turn waste into biofuels.

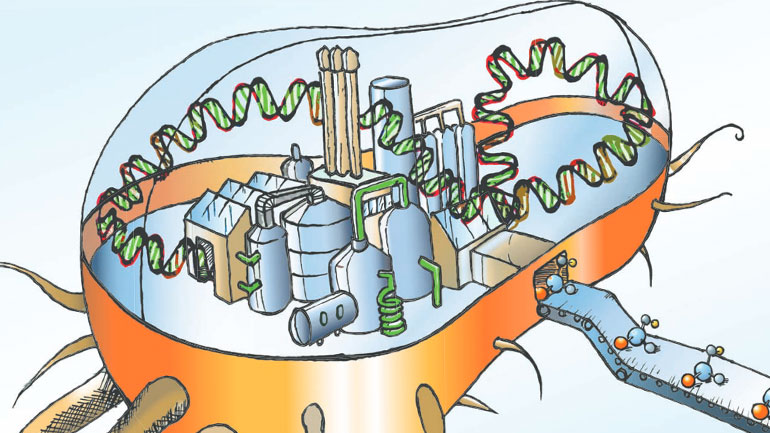

Until now, converting organic waste into fuel has not been economically viable. Excessively high temperatures and too much energy were required. Researchers at the Technical University of Munich (TUM) managed to significantly reduce the temperature and energy requirements for an integral step of the chemical process by using a novel catalyst concept: they confined the reaction to small spaces inside zeolite crystals. They published their findings about enhancing the effectiveness of their reaction and the restraint space where the reaction occurs in two papers of the journal "Nature Communications".

New process allows or decentralised chemical production

Today, electricity can be produced almost everywhere – using wind, water, and solar power plants. Therefore, chemical production should be decentraliced as well, reasons Johannes Lercher, who heads the Chair of Technical Chemistry II at TU Munich. However, thus far chemical processes require a lot of energy, which cannot always be provided everywhere. Therefore, Lercher and his team set out to develop new possibilities and processes for the distributed production of chemicals. And they succeeded: the scientists demonstrated that the temperature required for splitting carbon-oxygen bonds in acidic aqueous solution can be drastically reduced using zeolite crystals. The process also ran much faster than without the zeolite catalysts.

Nature as a role model

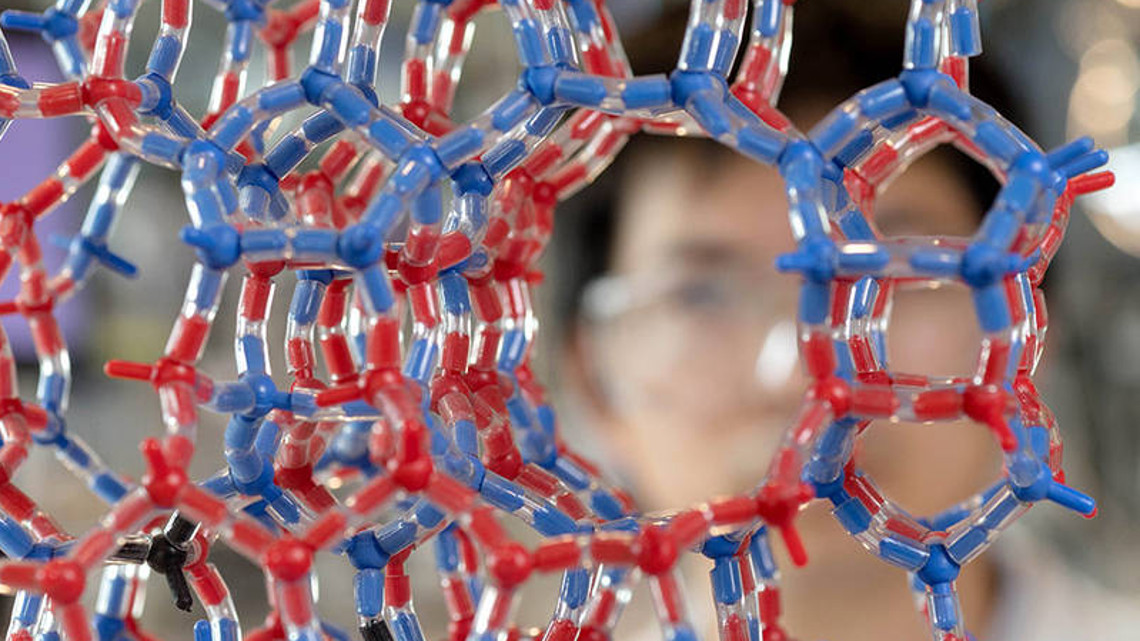

To find this mechanism, the scientists looked at nature as a role model: In biological systems, enzymes with small pockets in their surface accelerate chemical processes. Lercher explains: “While searching for suitable catalysts that accelerate the reaction, we stumbled upon zeolites – crystals with small cavities in which the reactions take place under cramped conditions comparable to those in enzyme pockets.” In order to test their theory, the researchers compared the reactions of carbon compounds with acids in a beaker to the same reactions in zeolites. The result: In the crystal cavities, where the reacting molecules meet upon the hydronium ions of the acids, reactions run up to 100 times faster and at temperatures just over 100 °C. “Our experiments demonstrate that zeolites as catalysts are similarly effective as enzymes: Both significantly reduce the energy levels required by the reactions,” reports Lercher. “The smaller the cavity, the larger the catalytic effect. We achieved the best results with diameters far below one nanometer.”

Less space equals higher chances for reaction

The principle behind this improved reaction is the same as the one that allows geckos to walk on ceilings, Lercher continues: “The more contact points there are between two surfaces, the larger the adhesion. In our experiments, the organic molecules, which are in an aqueous solution, are literally attracted to the pores in the zeolites.”

Thus, the hydronium ions within the cavities have a significantly greater likelihood of bumping into a reaction partner than those outside. The result is an acid catalyzed chemical reaction that takes place faster and with lower energy input.

Of course, it will take some time before the new process can be deployed as a garbage-to-fuel transformer in the field: “We are still working on the fundamentals,” emphasizes Lercher. “We hope to use these to create the conditions required for new, decentral chemical production processes that no longer require large-scale facilities.”

jmr